Digitalization is moving at warp speed, and the manufacturing industry is not left untouched in this rapid change. Technology evolutions are one fundamental cause for this change, and one such technological revolution is the Internet of Things or IoT. IoT in the realm of manufacturing itself is the adaptation of physical devices on the internet, enabling them to communicate, thereby collecting data and utilizing real-time analytics. Cloud-based software leader Zoho is now making this usage of IoT available to manufacturing of any size through Zoho’s IoT platform.

We are talking about how Zoho IoT can transform manufacturing, reducing costs, boosting productivity, and increasing efficiency in overall productivity in this article. We are one of the best Zoho Consulting Partner make these innovations simple and clear for everyone so they understand how IoT can change the face of manufacturing.

1. What is Zoho IoT?

Zoho IoT is one strong cloud platform for manufacturing companies that have helped them manage their connected devices. This simply means that the entire business can collect, analyze, and monitor data from machines, sensors, and other physical assets in real time. That gives some great insights to organizations into how their machinery performs, leading organizations to take better decisions and be more efficient.

IoT is no longer a space only for technically oriented companies; Zoho IoT gets this job done by providing manufacturers user-friendly tools and an interface through which they can monitor their operations hassle-free.

2. Role of Zoho IoT for the Manufacturing World

Machines and equipment are the backbone of any manufacturing unit. Break or inefficiency leads to expensive downtimes and lost productivity. IoT becomes crucial because it:

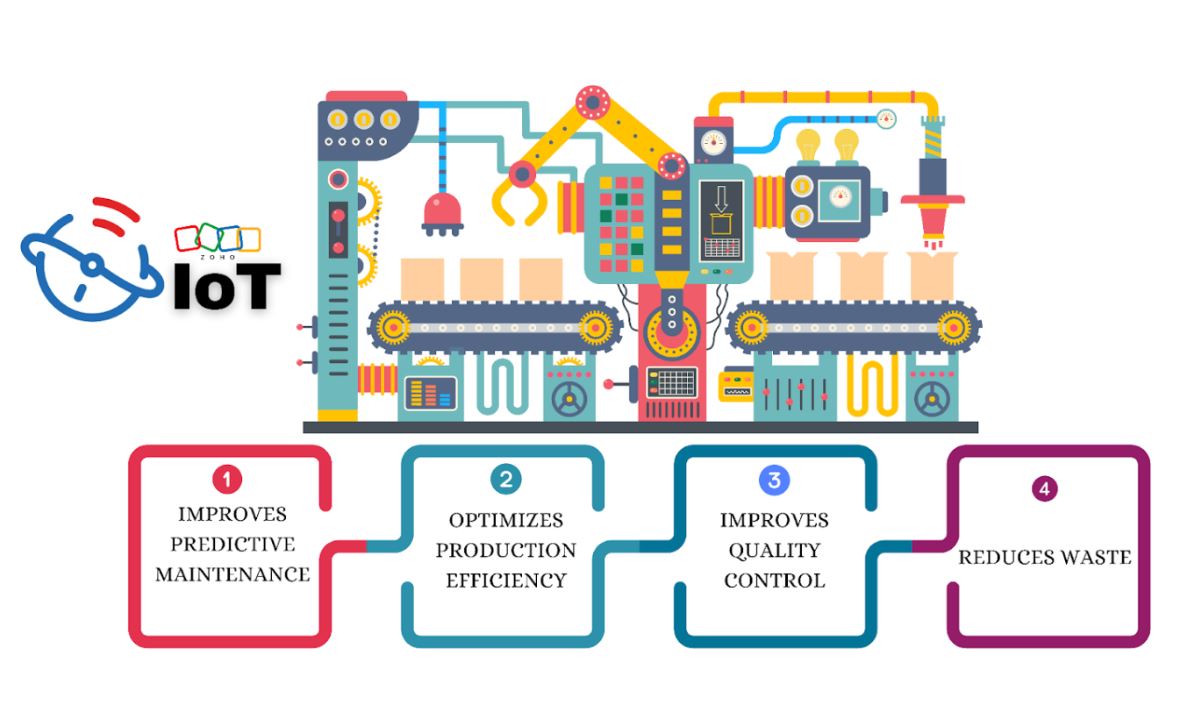

- Improves Predictive Maintenance: IoT supports manufacturers to monitor the condition and performance of their machines. Machines can be mounted with sensors in order to sense wear and tear or any types of malfunctioning. Such a measure helps avoid a breakdown, which calls for repair, thereby saving costs that come from repairing it and also recovering from unplanned downtimes.

- Optimizes Production Efficiency: Manufacturers can monitor the production line live through the connection of devices. They can then identify some bottlenecks or inefficiencies and change production schedules to ensure that production is done on optimal levels.

- Improves Quality Control: The Internet of Things allows companies to collect data from the performance of healthy machines. This kind of data can be analyzed, allowing for better product quality to improve by identifying and solving issues faster.

- Reduces Waste: IoT Monitoring of resources and energy usage allows manufacturers to reduce waste in materials, time, and consumption of energy while increasing sustainability in their operations.

3. Zoho IoT’s KIoT’satures for Manufacturing

Now that we have a good idea of why IoT is necessary for manufacturing let’s look at some of the specific ways Zoho IoT empowers businesses in the industry:

A. Real-time Monitoring

Zoho IoT monitors machines, equipment, and devices in real time. Manufacturers can trace the status of their operations, monitor the health of the machines, and get alerts in case any abnormalities are found. It results in less down time, faster repairs, and increased production efficiency.

For example, if a temperature shoots up to unsafe limits, the IoT can alert the maintenance team to take action immediately before the machine breaks up.

B. Automated Workflows

Using Zoho IoT, manufacturing units can automate several processes. Hence, a sensor can be sent a message saying that there is some part of this machine, which is wearing out, and it can generate an automatic order for replacement parts based on the reading. This reduces frequent manual checks by ensuring all important parts are available all the time, thus preventing untimely shutdowns.

C. Predictive Maintenance

Predictive maintenance is one of the greatest applications of IoT in manufacturing. Manufacturers can use sensor data to predict when a machine will require maintenance before it fails. With Zoho IoT, manufacturers can make data-informed maintenance plans, reduce their repair costs, and ensure smooth production runs.

D. Data-Driven Decision Making

Zoho IoT collects humongous amounts of data by machines and sensors. This data will be analyzed to help manufacturers make data-driven decisions. Be it optimization of production lines, inventory management, or reduction in energy consumption, acting based on accurate data is invaluable for improving operations .

E. Remote Management

One of the most impressive advantages of Zoho IoT is its simplicity in monitoring devices over a network. This enables a manufacturer to monitor and control machines even though the locations may be in different places across the globe. This really works well for firms that should seamlessly integrate all locations to have an essentially global presence.

4. Enhancement of Manufacturing Operations with Zoho IoT

Given that we have passed through the key features let’s now see how Zoho IoT particularly benefits manufacturing operations:

A. Optimizing Resource Utilization

Zoho IoT ensures that manufacturers use their resources to maximum levels. Accumulation of data on energy use, machine performance, and material usage will result in using resources at maximum efficiency. It also reduces costs along with waste and improves the sustainability of its operations.

B. Enhancing Supply Chain Management

IoT enhances visibility throughout the supply chain. It is made possible to track the movement of materials and finished goods in real time using Zoho IoT integrated into inventory and supply chain management systems. This avoids stockouts, optimizes production schedules, and keeps a supply chain much more responsive and agile.

C. Speedier Problem Resolution

Real-time monitoring can forecast some issues to be raised earlier, and hence, allow action to be taken promptly in time to correct the matter before it’s too late. This consequently means less time waste and turn times on orders for customers. Manufacturers would also ensure quality products were consistently delivered and met customer orders much faster.

D. Enhancing Safety and Compliance

Manufacturing environments are dangerous, with heavy machineries and intricate equipment. In such environments, Zoho IoT will help manufacturers track safety conditions in real-time. The sensors can feel the hazard levels of gas, temperature fluctuations, or vibrations reflecting risks. IoT ensures adherence to safety regulations and protects the workers.

5. The Future of Manufacturing with Zoho IoT

This is where Zoho IoT comes into play: for, as the pinnacle of manufacturing, a future bright with all things digital, we will continue to see that the industry becomes smart, efficient, and sustainable.

With advances in machine learning and AI, IoT will keep on growing and continue to evolve with an even stronger predictive ability, intelligent automation, and more profound insights. Zoho IoT continuously innovates and adds new features and integrations to keep manufacturers ahead.

In the future, those manufacturers adopting IoT early will have an edge of competition as they are enabled to respond faster to changes in the market. They also save on operating costs and improve the time to deliver products.

6. Introduction to Zoho IoT

Zoho IoT is relatively easy for manufacturers to begin with, thanks to the intuitive design that allows for very easy connection of devices and viewing data and creating workflows. Zoho offers deep support, including training, onboarding, and integration services, to ensure that a firm of any size reaps the benefit from IoT.

The platform hence enjoys good integration with other Zoho products, such as the respective Zoho Inventory, Zoho CRM, and Zoho Analytics, therefore offering a full suite of solutions for managing operations.

Conclusion

Zoho IoT is going to revolutionize the manufacturing industry by making it more connected, efficient, and data-driven. The following are some of the leanings manufacturing companies may obtain: considerable cost savings, improved quality of production, and higher productivity through real-time monitoring, predictive maintenance, and automated workflows. Thus, with further developments in this technology, Zoho IoT is going to keep manufacturers competitive in an increasingly digital world.

For any manufacturer, embracing IoT is no longer an option but a necessity to compete in the current fast-paced competitive markets. Zoho IoT provides the wherewithal and solutions to make that journey easily realized and connect manufacturing to its full potential.